In-Mold Decorations: Revolutionizing Manufacturing Specifications

In-Mold Decorations: Revolutionizing Manufacturing Specifications

Blog Article

Grasping In-Mold Decorations: Strategies, Patterns, and Best Practices for Ideal Outcomes

In the realm of production, the art of in-mold designs stands as an essential element of item layout and manufacturing. In-Mold Decorations. By diving into the approaches, fads, and ideal techniques that underpin effective in-mold decor procedures, organizations can open a world of opportunities that not just boost the visual attraction of their items however likewise improve production efficiency and reinforce customer engagement.

Material Choice

Product selection is an important element of grasping in-mold designs, as it directly impacts the high quality and durability of the end product. When picking materials for in-mold decorations, it is vital to take into consideration variables such as compatibility with the molding procedure, the preferred aesthetic outcome, and the ecological conditions the product will certainly face. Thermoplastic products like abdominal, polypropylene, and polycarbonate are typically made use of for in-mold designs because of their versatility and ability to achieve intricate styles. These materials supply exceptional moldability, enabling producers to produce complicated shapes and patterns with accuracy.

Furthermore, the selected material must possess great attachment properties to ensure that the design sticks firmly to the substratum throughout the molding process. Adhesion in between the product and the decor is important for protecting against delamination and guaranteeing resilient aesthetic appeal. Additionally, materials with high warm resistance are favored for in-mold decorations, especially for products that will certainly be revealed to raised temperature levels during their lifecycle. By thoroughly choosing the proper product for in-mold decors, manufacturers can enhance the overall high quality and toughness of their items, fulfilling the assumptions of both end-users and customers.

Layout Innovation

An essential consider progressing the area of in-mold designs is the constant exploration and execution of layout advancement methods. Design innovation plays a crucial duty in improving the aesthetic appeal, capability, and general quality of items produced using in-mold decoration procedures. By integrating innovative layout aspects, producers can separate their products in the market, bring in customers, and stay in advance of competitors.

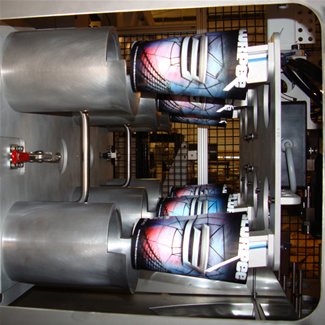

Among the crucial aspects of layout advancement in in-mold decorations is the assimilation of elaborate patterns, textures, and graphics that were formerly testing to accomplish with traditional decor methods. Advanced modern technologies such as 3D printing and digital layout tools make it possible for designers to develop complex and thorough designs that can be effortlessly moved onto shaped parts. In addition, making use of vivid shades, metallic surfaces, and unique effects like gloss or matte appearances can additionally elevate the visual allure of in-mold decorated products.

In addition, design advancement extends beyond aesthetics to include useful enhancements such as ergonomic shapes, incorporated attributes, and customizable aspects that accommodate specific individual demands. By welcoming design development, suppliers can unlock new possibilities for customization, item, and creativity distinction in the affordable landscape of in-mold decors.

Manufacturing Performance

Effective production procedures are crucial for equating the ingenious designs created in the field of in-mold decorations right into top notch finished items that meet market demands and customer assumptions. In the realm of in-mold decorations, manufacturing effectiveness encompasses numerous crucial aspects that add to the general success of the manufacturing procedure.

Automation not only accelerates the production process but likewise improves precision and repeatability, leading to a much more consistent and top notch end product. In general, an alternative technique to production effectiveness is vital in making best use of the possibility of in-mold decor strategies and attaining ideal results in the competitive market landscape.

Quality Control Steps

What are the key approaches for guaranteeing stringent high quality control measures in the world of in-mold decorations? Quality control procedures are paramount in in-mold decor processes to make sure the production of perfect and high-quality completed items.

Using innovative technologies such as automatic examination systems can likewise boost the quality control process by giving accurate and trustworthy information for evaluation. These systems can spot flaws that might be missed out on by manual assessments, therefore improving overall product top quality and uniformity.

Routine training and growth programs for staff members involved in the in-mold design procedure can additionally add to maintaining premium requirements. By enlightening team on best practices, high quality expectations, and the value get redirected here of focus to information, firms can cultivate a society of quality consciousness throughout the organization.

Consumer Appeal

To improve the marketability of in-mold design products, recognizing and catering to consumer choices play a vital duty in identifying their allure and success. Using customization choices such as personalized layouts, color variants, and textural elements can substantially enhance the charm of in-mold decoration products.

Conclusion

In-mold decorations use a effective and flexible means to boost item looks. By meticulously choosing products, embracing innovative layouts, optimizing manufacturing processes, carrying out quality assurance actions, and focusing on customer allure, makers can accomplish optimum outcomes. It is critical for firms to consistently adjust and enhance their methods to stay competitive on the market. In-Mold Decorations. Mastering in-mold decorations calls for an all natural technique that thinks about all elements of the manufacturing procedure to make sure success.

In the world of manufacturing, the art of in-mold decors stands as an essential aspect of item style and manufacturing. Style innovation plays a crucial function in enhancing the visual appeal, performance, and general high quality of products produced using in-mold decor processes.One of the vital aspects of layout development in in-mold decorations is the combination of intricate patterns, appearances, and graphics that were previously testing to attain with conventional decor methods.Reliable production processes are essential for equating the cutting-edge designs established in view the area of in-mold decorations right into premium ended up products that satisfy market needs and consumer expectations. Providing customization alternatives such as customized styles, shade variations, and textural elements can considerably enhance the appeal of in-mold decoration items.

Report this page